1)Made of mild steel or Q235

2)HDG with powder coating

4)Octagonal, round

5)Lower cost

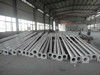

Details about street lamp poles

1.Processing technic

Road lamp post of our company is made from quality sheets through bending, forming, automatic welding, hot dip galvanization and powder coating. We owned advanced production-line, it included Flatting machine, Steel plate shearer, bending machine, Auto-closed up machine, submerged arc welding machine and powder coating line, and our workmanship and quality control was achieved high opinion from our clients.

2.Detailed Features

Pole’s height | 6m to 12m |

Shape of pole | Round conical; Octagonal tapered; Straight square; Tubular stepped; Shafts are made of steel sheet that folded into required shape and welded longitudinally by automatic arc welding machine |

Brackets/ Arm | Single or double brackets/ arm are in the shape and dimension as per customers requirement |

Length | Within 14m once forming without slip joint |

Wall thickness | 3.25mm to 5mm |

Welding | It has past flaw testing. Internal and external double welding makes the welding beautiful in shape. And confirms with international welding standard of CWB |

Jointing | Jointing of pole with insert mode, inner flange mode, face to face joint mode. |

Base plate mounted | Base plate is square or round in shape with slotted holes for anchor bolt and dimension as per customer’s requirement. |

Ground mounted | The length buried underground as per customers requirement. |

Galvanizing | Hot dip galvanization with thickness of 80-100µm average in accordance with Chinese standardGB/T 13912-2002 or American standard ASTM A123, IS: 2626-1985. |

Powder coating | Pure polyester powder painting, color is optional according to RAL Color standard. |

Wind Resistance | Against wind pressure of 160Km/h |

Manufacturing | According to GB/T 1591-1994. |

Quality Control | We control the quality according to the flow of ISO9001-2008. Quality is employed at every stage of production to ensure the product compliance to the specifications/standards. Careful inspections are carried out by highly trained inspection engineers as per the defined procedures from raw material stage to finished product and delivery. Prototype assembly of towers is carried out in the plant. |

Certificates | CE |

light pole